ADVANCE ULTRASONIC THICKNESS GAUGE B6-C

The metal thickness gauge is used for thickness measurement of products from metals and their alloys, thickness measurement under protective coatings, thickness measurement of non-metallic products (plastic, ceramics, and others), which allow the use of ultrasonic inspection methods.

BASIC ULTRASONIC THICKNESS GAUGE- B2

The device is designed to measure the thickness of products from metallic and nonmetallic materials (sheets, tanks, pipes, pipelines, bridges, metal containers, transport and other structures, including highly corroded, with incrustation, etc.) during operation to determine their corrosion state on or after the manufacture of energy, tube, engineering, shipbuilding, transportation and other enterprises.

Crack Depth Gauge

Crack depth meter 281M - High-precision instrument for measuring the depth of cracks exposed on various metals and alloys (incl. stainless steel, duraluminum), previously detected by other methods.

The operating principle of the Crack Depth Meter – AC electro potential measuring that provides prompt and precise depth test (in comparison to traditional methods).

The device is the most efficient in combination with other crack-revealing methods: magnetic particle, capillary or eddy-current.

General Coating Thickness Gauge MG 405

MG-405 is designed for highly precise measurements of varnish coating thickness, plastics – isolating layers or galvanic layers on steel, aluminium, brass or copper.

It may also be used for precise car body controlling, determining the thickness of the varnish (lacquer) and finding the repaired places.

Hardness Case Depth Tester

Surface hardening improves the wear resistance and fatigue strength of dynamically stressed components. These functional characteristics are mainly determined by surface hardness, hardening depth and residual stress.

An essential quality feature of the surface hardening process is the thickness of the hardened layer (SHD). Currently, the hardened layer can only be tested in random samples using destructive methods, a procedure that is both costly and time-consuming.

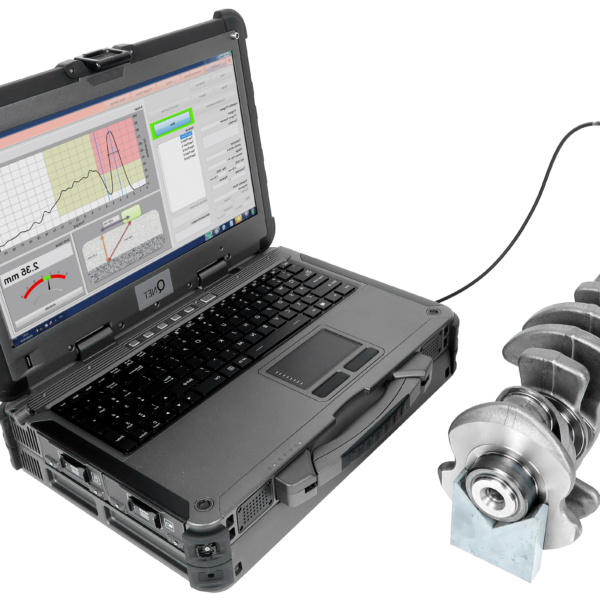

Holiday Detector

Detection of cracks, porosity, inadmissible thinning and other discontinuities of internal and external protective dielectric

coatings (varnish, paint, powder, film, bituminous and other dielectric coatings) by application of pulsed high test voltage and

fixing electrical breakdown in places of discontinuity or inadmissible thinning.

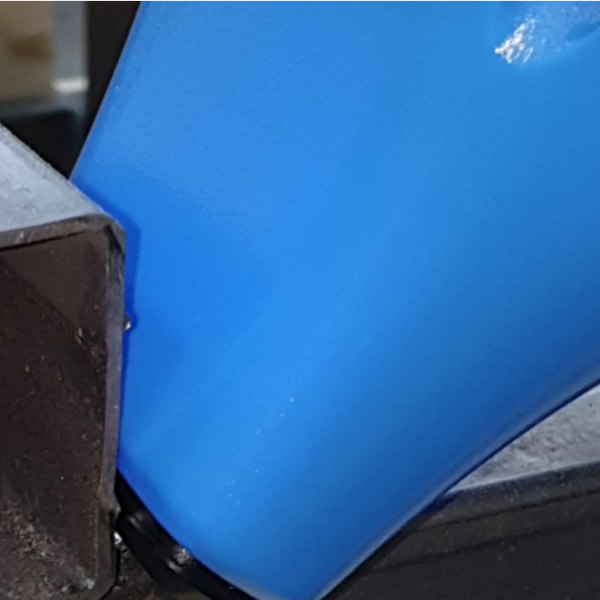

LEEB HARDNESS TESTER TKM‑359CE

High precision rebound/leeb hardness tester TKM‑359CE intended for quick measuring of metal items in laboratorial, manufacturing, and field conditions.

The leeb hardness tester is intended for non-destructive testing of production quality in metallurgy, mechanical engineering, aircraft, shipbuilding, atomic industry, oil and gas industry.

Leeb hardness tester functions by Leeb method.

Magnetic Eddy Current Flaw Detector

Magnetic-eddy current flaw detector VID-345 is intended for detecting cracks and measuring their depth, detecting stress- corrosive cracks in metal ferromagnetic constructions, even under layer of corrosion and/ or protective coating.

Flaw detector enables to measure depth of corrosive damage as well as thickness of protective coating.

The device combines magnetic and eddy-current methods for flaws detection, which enables the user to control products with rough corroded surface and to measure through the layer of insulating coating of variable thickness without any additional readjustment.

MULTIFUNCTION COATING THICKNESS GAUGE K6-C

K6-C Multifunctional Coating Thickness Gauge: Supports Nickel electroplating and a single device works with multiple probes.

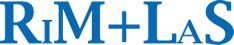

UCI HARDNESS TESTER TKM‑459CE

High precision UCI hardness tester TKM-459CE intended for quick measuring of metal items' hardness in laboratorial, manufacturing, and field conditions.

The device is intended for non-destructive testing of production quality in metallurgy, mechanical engineering, aircraft, shipbuilding, atomic industry, oil, and gas industry.

Portable UCI Hardness tester functions by UCI method (Ultrasonic Contact Impedance).

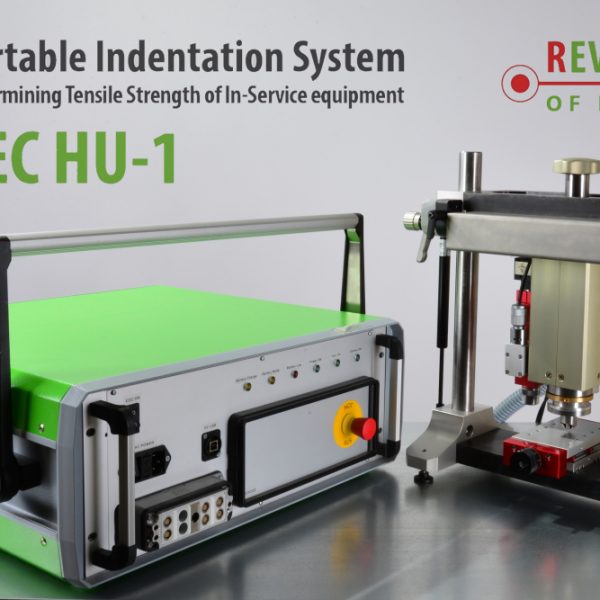

UPIS-MUBATEC HU-1

Mubatec HU-1 device for measuring hardness and mechanical properties metal